innovates Packaging

Company

TOMOKU VIETNAM CO., LTD

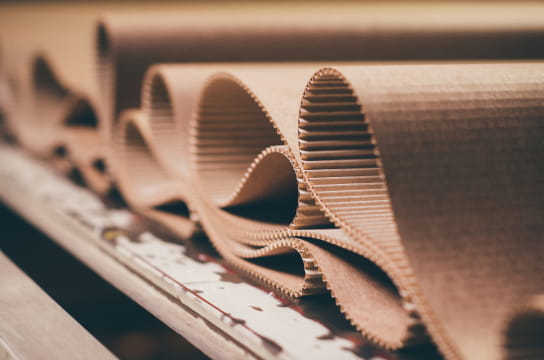

Tomoku Vietnam Co., Ltd., established in 2013, is a 100% subsidiary of Tomoku Co., Ltd. of Japan. Located in My Phuoc Industrial Park near Ho Chi Minh City, our 60,000㎡ factory specializes in the manufacturing of corrugated cardboard sheets and boxes, supplying products to both domestic and overseas markets.

With advanced production lines, automated inspection systems, and supervision by Japanese engineers, we ensure consistent quality that meets international standards. Certified under ISO 9001 and FSC®, our operations emphasize environmental responsibility and sustainable resource use — delivering reliable, high-quality packaging solutions that support our customers across industries.

Company

TOMOKU VIETNAM CO., LTD

Representative

KIBI KYOSUKE

Address

Lot B-5B1-CN, Road DE4&NE5A, My Phuoc IP3, Thoi Hoa Ward, Ho Chi Minh City, Vietnam

Establish

April 11, 2013

Employees

150

Capital

USD 9.2 million

Business

Manufacturing and sales of corrugated cardboard products

Site Area

60,000㎡ (Building Area: 31,191㎡)

Located in My Phuoc Industrial Park 3,

approximately 45 km from central Ho Chi Minh City (about 90 minutes by car).

Company

TOMOKU CO., LTD

Representative

NAKAHASHI MITSUO

Address

4th Floor, Marunouchi Mitsui Building, 2-2-2 Marunouchi, Chiyoda-ku, Tokyo, Japan

Establish

May 27, 1949

Employees

1,173 (Consolidated: 3,830)

Capital

JPY 13,669.87 million

Listed Market

Tokyo Stock Exchange (Prime Market), Sapporo Securities Exchange

Corrugated Container and Display Carton

Housing

Transportation and Logistics

Company

KHANG THANH MANUFACTURING CO., LTD

Representative

KIBI KYOSUKE

Address

– Representative Office

5th Floor, Sky View Building, 41A Nguyen Phi Khanh, Tan Dinh ward, District 1, Ho Chi Minh city, Vietnam

– Factory 1

AMATA IP: Lot 103/6 Road 5, Long Binh Industrial Park (Amata), Long Binh ward, Bien Hoa city, Dong Nai province, Vietnam

– Factory 2

AMATA IP: Lot 230 Road 4, Long Binh Industrial Park (Amata), Long Binh ward, Bien Hoa city, Dong Nai province, Vietnam

Establish

25 March 2005

Business

Product Design – Prepress CTP

Packaging Printing Services

Finished Product Packaging

Corrugated Container is an excellent packaging product for the environment.

Sustainability and Recycling Initiatives

At Tomoku Vietnam, we are committed to creating a sustainable society through resource circulation. Our production system emphasizes the reuse and recycling of materials used in corrugated packaging, transforming waste paper into new boxes through an efficient closed-loop process.

We also focus on reducing environmental impact by minimizing waste, saving energy, and developing eco-friendly packaging that supports both our customers’ logistics and the global environment. Through these initiatives, Tomoku continues to promote a responsible and sustainable future.

Recycling of Used Paper

Waste Reduction and Energy Efficiency

Eco-Friendly Product Development

Business

Planning & Design

We provide packaging design and planning services tailored to each customer’s product and logistics needs.

By combining functionality with visual appeal, we create corrugated packaging that enhances both protection and brand value.

Our sales team includes a Japanese manager and a large number of Vietnamese staff, enabling smooth multilingual communication and reliable support.

Raw Material Procurement

Leveraging the Tomoku Group’s global network, we source high-quality linerboard and medium paper from reliable domestic and international suppliers.

This ensures stable supply, consistent quality, and flexibility to meet diverse requirements.

Manufacturing & Sales

At our modern factory equipped with advanced production and inspection systems, we manufacture corrugated sheets and boxes with precision and speed.

Our products are supplied to various industries in Vietnam and abroad, backed by Japanese quality standards and local responsiveness.

Feature

Japan-Standard Facilities

Our factory was designed and constructed according to Japanese standards to ensure long-term durability, cleanliness, and environmental protection.

Unlike conventional factories in Vietnam, which often use brick and mortar structures prone to aging, Tomoku Vietnam’s steel-frame facility provides superior insulation and dust control. This environment allows us to maintain consistent production quality and hygiene standards that meet global expectations.

Flexible Production and Supply

We maintain a highly flexible production system capable of handling both large-scale export orders and small, customized batches.

With our extensive equipment lineup and efficient production planning, we can accommodate automated mass production as well as manual assembly work. This enables us to respond quickly to diverse customer needs—from global corporations to local manufacturers—while maintaining stable quality and delivery schedules.

Advanced Quality Control

Quality is at the core of everything we do. Our plant is equipped with advanced machinery and a dedicated QC team of around ten specialists who monitor every stage of production.

Under the supervision of Japanese engineers stationed on-site, we ensure strict traceability of raw materials and finished products through barcode management. Our in-house testing facilities verify the strength and performance of every batch, ensuring consistent “Made in Japan” quality.

Environmental and Workplace Commitment

Tomoku Vietnam operates as an environmentally responsible factory. We use gas boilers to reduce CO₂ emissions, hold FSC® certification and local environmental licenses, and recycle all corrugated waste into reusable materials.

Inside the factory, workflow layouts are optimized for safety and efficiency. Through continuous training, skill development, and leadership promotion, we foster a workplace that values both people and sustainability.

For inquiries about processing, quotations,

or delivery schedules, click here.

Contact Us Online

Available 24 hours a day.

We will reply within 1–2 business days after receiving your form.

(Except Vietnamese public holidays)

Certifications

ISO 9001 – Quality Management System

Tomoku Vietnam is certified under ISO 9001, the international standard for quality management systems.

This certification demonstrates our commitment to delivering consistent, high-quality corrugated packaging that meets customer requirements and international standards. We continuously improve our production and inspection processes to ensure reliability and customer satisfaction.

FSC® – Responsible Forestry and Sustainable Sourcing

We have obtained FSC® certification, which ensures that our corrugated products are made from responsibly sourced materials that support sustainable forest management. Through this certification, Tomoku Vietnam contributes to reducing environmental impact and promoting ethical, eco-friendly manufacturing practices.

FAQ

What types of products does Tomoku Vietnam manufacture?

We specialize in manufacturing corrugated cardboard sheets and boxes. Our products are used for various industries including manufacturing, logistics, and consumer goods.

We also provide design support to create packaging that best suits each customer’s products.

Can you handle custom designs or special sizes?

Yes. We can produce custom sizes, shapes, and printed designs according to customer requirements. Our in-house design team and modern printing equipment allow us to deliver flexible and high-quality solutions.

How do you manage product quality?

We apply strict quality control under ISO 9001 standards. Each batch is inspected using barcode traceability and physical strength testing in our in-house quality lab. Japanese engineers also supervise the production process to maintain consistent standards.

Can you support communication in multiple languages?

Yes. Our sales team is led by a Japanese manager and supported by a large number of Vietnamese staff members, allowing us to handle inquiries smoothly in multiple languages and provide reliable assistance.